Displaying items by tag:

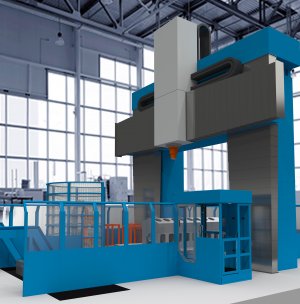

Portal milling machine of Gantry type design WPA

Portal milling machine of Gantry type design WPA

ŠMT portal milling machine of Gantry type design with variable clamping area in the form of a clamping plates, optionally equipped with rotary or carousel table. The machine travel is 1m extended for the automatic pick up of milling heads at the end of the workplace. Sliding columns with a vertically movable cross rail are connected with a fixed beam, that reinforces the whole frame of the machine.

Portal milling machine of table type design WP

Portal milling machine of table type design WP

ŠMT portal milling machine of table type design with clamping plate size according to customer‘s request. Table travel is 1m longer than plate length. Table load capacity according to the clamping plate size is 100 - 250 t. Fixed columns with a vertically movable cross rail are connected with a fixed cross beam that reinforces the whole frame of machine. The result is a very high rigidity and accuracy of the complete machine.

Milling and boring heads

Wide range of milling and boring heads enables you machining according to your requirements. More than 30 types of heads are available. Below are the most commonly used. For more information, contact our service department.

Change of tools

ŠMT offers automatic and robotic change of tools into spindle of machine or spindle of various milling heads.

Multi-functional machine type S-MT

Multi-functional machine type S-MT is able to offer to you a complete machining with different types of accessories incluiding the measuring by one clamping. Thanks that customer needs smaller installation area and can also reduce the number machines.

COMPLETE MACHINING IN ONE CLAMPING

ŠMT HCW 2000–4000 series

Horizontal boring and milling machines ŠMT are successful all over the world, since they are capable to machine accurately and efficiently large workpieces of complex shapes, such as turbines, parts of windmills or large motor blocks.

Two-step gearbox built into the ram allows this type of machine to reach extreme out travels in the ram (Z) and the spindle (W) travels together with very high revolutions. This up-to-date concept of the newest type of ŠMT horizontal boring and milling machine enables use of the most advanced machining tools available on the market and it also extremely improves the customer’s productivity.

ŠMT HCW 1–4 series

Horizontal boring and milling machines ŠMT are successful all over the world, since they are capable to machine accurately and efficiently large workpieces of complex shapes, such as turbines, parts of windmills or large motor blocks.

Machines' gearbox (Two-step; Three-step) allow transmitting of extremely high torque in the spindle or tool for rough machining together with the possibility of high revolutions for final machining.

ŠMT FCW series

Horizontal boring and milling machines ŠMT are successful all over the world, since they are capable to machine accurately and efficiently large workpieces of complex shapes, such as turbines, parts of windmills or large motor blocks.

The FCW horizontal boring machines will find application in dusty working environments and jobs including cast iron, plastic material or GFK machining.

They are also the best solution for machining box-type component parts of complex shapes for various industries including power generation, ship-building, mining, chemical, booms and transport equipment manufacturing.