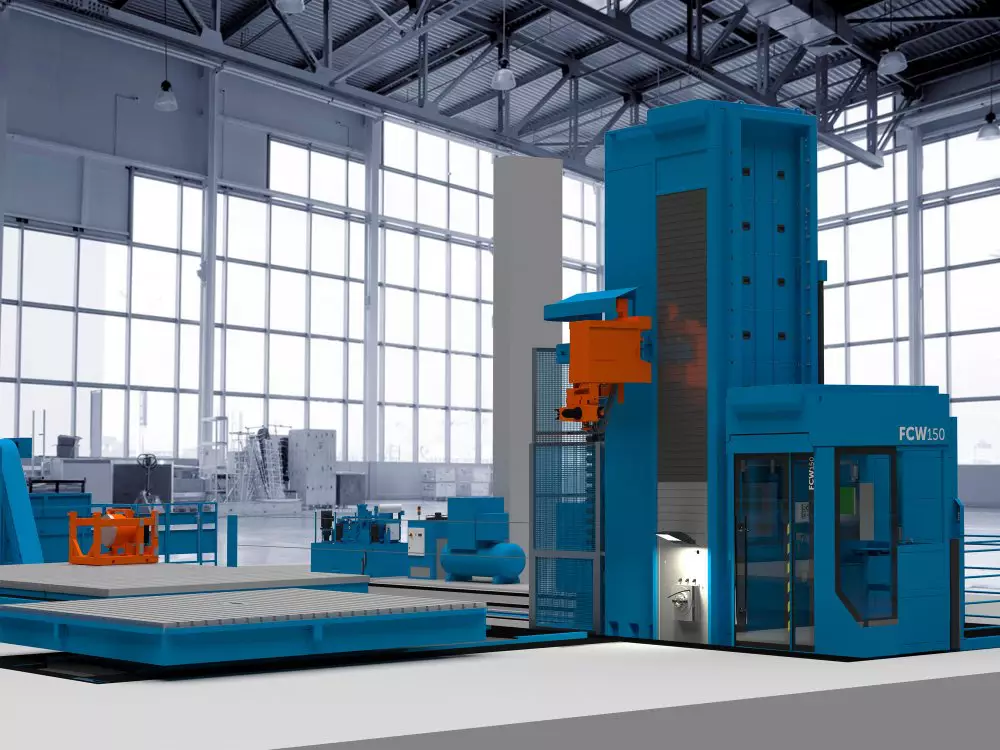

Horizontal boring and milling machines ŠMT are successful all over the world, since they are capable to machine accurately and efficiently large workpieces of complex shapes, such as turbines, parts of windmills or large motor blocks.

The FCW horizontal boring machines will find application in dusty working environments and jobs including cast iron, plastic material or GFK machining.

They are also the best solution for machining box-type component parts of complex shapes for various industries including power generation, ship-building, mining, chemical, booms and transport equipment manufacturing.

- high machine reliability

- simple maintenance

- original aesthetic design

- high efficiency of price vs. performance

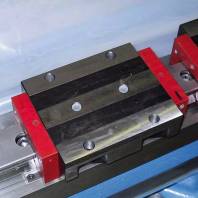

LM GUIDEWAYS

Linear rolling-contact bearings for the column movement on the machine bed and headstock movement on the column

MASTER-SLAVE SYStEM

The toothed rack fitted into the bed, engaging the displacement box at the column traverse unit (the Master-Slave system)

UFK 5-AXIS MACHINING HEAD

FCW machine can be eqiupped with universal 5-axis UFK 600 as a standard accessory for its higher flexibility and variability

This machine of a quill-type design is made from a box-shaped grey iron casting. Automatic ram dropping compensation is performed during the whole out travel of the ram according to the weight of the technological accessories applied.

The Heidehain measuring scale for direct ram extension measurement with compensation of the longitudinal thermal expansion of the ram is a proprietary ŠMT patent.

|

|

FCW 140 |

FCW 150 |

FCW 160 |

|

Spindle diameter (mm) |

140 |

150 |

160/180 |

|

Main motor power (kW) |

37 |

52 |

64/81 |

|

Max. spindle speed (rpm) |

3 000 |

3 000 |

3 000/3 500 |

|

Sleeve extension Z axis (mm) |

1 000 |

1 200 |

1 500 |

|

Sleeve extension W axis (mm) |

900 |

900 |

1 000 |

|

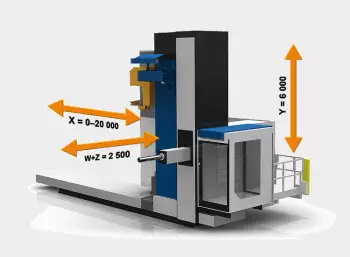

Max. headstock traverse Y axis (mm) |

5 000 |

4 000 |

6 000 |